The new report “Efficiency Now – Overcoming Internal Barriers to Industrial Energy Efficiency” recently released by the Energy Efficiency Movement spotlights old and new barriers industries face when it comes to implementing energy efficiency measure into their business. The report provides an in-depth look at the current state of industrial energy efficiency, drawing insights from a global survey conducted between February and April 2025 with 294 organizations across various sectors. The key message outcoming from it is that despite the clear benefits of energy efficiency in reducing emissions, lowering costs, and boosting competitiveness, many companies continue struggling to take meaningful action.

Regulatory uncertainty, geopolitical risks, and financial constraints are among the factors slowing down progress. Additionally, inconsistent market signals make it difficult for businesses to commit to long-term efficiency investments. Yet, energy efficiency remains a powerful lever for gaining a competitive edge—especially as new policies, like carbon border regulations, reshape the global economic landscape.

We will analyse the following factors:

1. Energy Efficiency: A Growing Priority Across Industries

2. Greatest challenges in energy efficiency for industries

2.1 Financial concerns

2.2 Adapting infrastructure

2.3 Insufficient skills

2.4 Strategic shortcomings

2.5 Data and control challenges

1. Energy Efficiency: A Growing Priority Across Industries

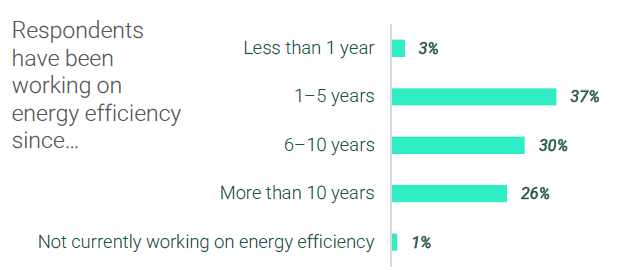

The 2025 Energy Efficiency Movement survey reveals that energy efficiency is not a new concept for most organizations—over 50% of respondents have been actively working on it for more than six years. Encouragingly, 84% report that their energy efficiency budgets are either stable or growing, with 68% seeing a clear year-on-year increase.

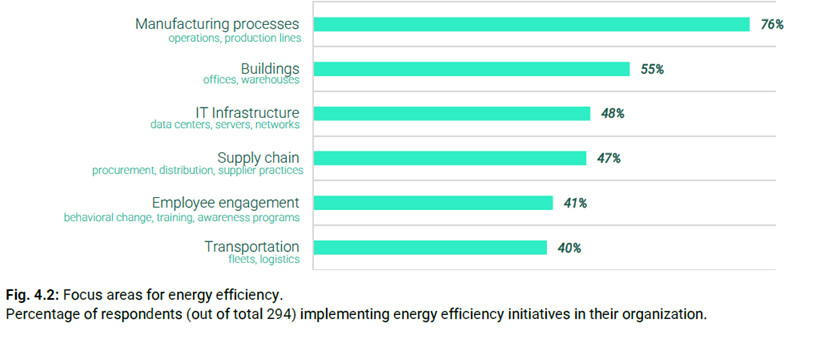

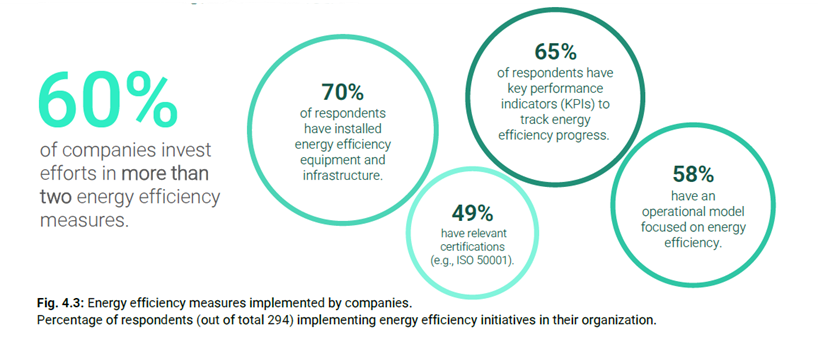

Manufacturing emerges as a primary area of focus, where efficiency initiatives are often most concentrated. In most organizations, energy efficiency infrastructure is already in place and supported by dedicated internal resources. 60% of the companies have invested in more than 2 energy efficiency measures indicating that a mix of technologies and solutions is the best choice addressing effective energy reduction targets of short, medium and long term period.

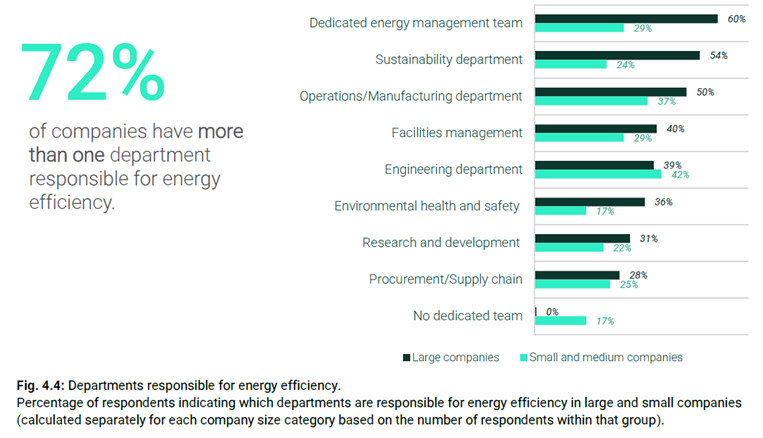

The majority have at least one department overseeing energy efficiency activities, and about half have a specialized energy management team. Interestingly, companies with such dedicated teams are significantly more likely to report consistent budget growth—suggesting that focused internal expertise contributes to stronger awareness of ROI and long-term benefits.

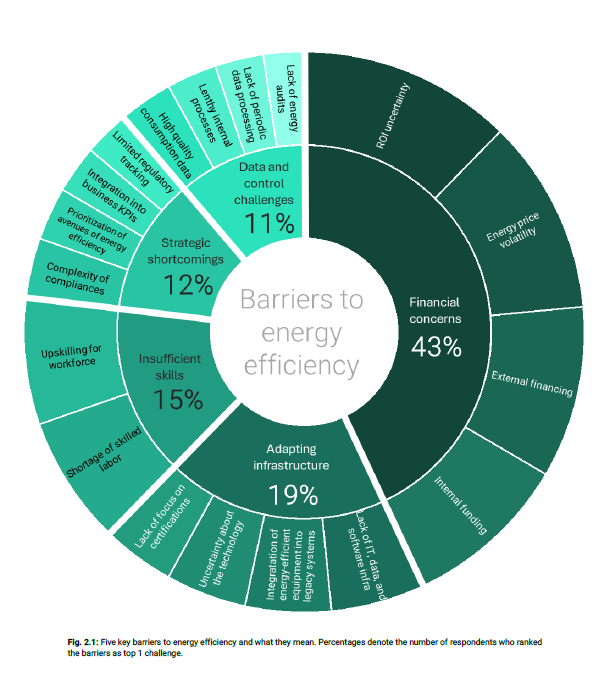

Yet the greatest challenges faced by companies in improving industrial energy efficiency continue to be:

- Financial concerns: 43%

- Adapting infrastructure: 19%

- Insufficient skills: 15%

- Strategic shortcomings: 12%

- Data and control challenges: 11%

In the following sections, we’ll take a closer look at the main internal barriers to energy efficiency identified by the survey and why overcoming them is key to unlocking even greater progress.

2. Greatest Challenges in Energy Efficiency for Industries

2.1 Financial Constraints: The Leading Barrier to Energy Efficiency

Financial concerns emerge as the most significant barrier to energy efficiency, with 43% of survey respondents identifying it as their top challenge. Despite growing awareness and increasing budgets, 84% of companies still believe that funding is insufficient to meet their efficiency goals.

Several factors contribute to this obstacle: uncertainty about the return on investment, the high upfront cost of energy-efficient technologies, and limited access to external financing—especially for small and medium-sized enterprises. These organizations often face tighter budgets and greater risk aversion, making it difficult to justify long-term investments with uncertain payback periods.

Larger companies, by contrast, tend to have better access to capital and benefit from economies of scale, making efficiency investments more financially viable. Nonetheless, even for large companies, unpredictable energy prices and evolving market conditions can delay decision-making and complicate strategic planning.

Overcoming Financial Barriers

While financial challenges remain a major hurdle, there are several practical steps companies can take to overcome them and accelerate energy efficiency adoption:

- Allocate Dedicated Funding and Unlock Budgets

- Set up a dedicated energy efficiency budget, possibly through a revolving fund that reinvests the savings from completed projects into new initiatives

- Simplify internal approval processes for projects with short payback periods (typically under 24 months) to encourage faster decision-making and implementation.

- Explore Alternative Financing Models

- Collaborate with technology providers or suppliers to explore models such as “Equipment-as-a-Service,” where capital costs are offset by ongoing savings.

- Consider external funding opportunities like green bonds, government subsidies, or multilateral programs. Look into OpEx-based financing, on-bill repayment solutions, and regional tax incentives.

- If internal resources are limited, consider working with external consultants to identify opportunities and build the right financial strategy.

- Manage Opportunities Strategically

- Build detailed business cases showing both direct and indirect benefits—such as energy cost savings, operational resilience, and brand reputation. Develop flexible ROI models that take energy price volatility into account.

- Map all potential efficiency opportunities across the organization and rank them based on impact, feasibility, and payback time using structured evaluation tools.

- Start with low-cost, high-return initiatives (“quick wins”) to demonstrate value and gain internal buy-in. Use clear KPIs to measure success and create a framework for scaling pilot projects across different sites or departments.

2.2 Infrastructure Limitations: A Hidden Obstacle to Efficiency

Infrastructure-related challenges are the second most cited internal barrier, with 19% of survey respondents ranking it as the top concern. While the long-term benefits of energy-efficient technologies are well understood, retrofitting existing systems in industrial environments may presents obstacles.

Many industrial facilities operate with legacy equipment designed for decades-long lifespans—such as motors, boilers, and compressors—which, while still functional, lack modern energy performance standards. Replacing or upgrading this equipment often involves high upfront costs, uncertainty around payback periods, and potential structural or layout modifications. Unlike new builds, retrofitting must work around existing constraints, making integration complex and costly.

Additionally, 42% of companies report difficulties integrating new energy-efficient solutions into existing operations, especially where hardware and software need to interface with outdated systems. This issue is amplified by the increasing reliance on digital infrastructure, where data, software, and control systems require cross-functional collaboration—something that 47% of respondents identify as a major challenge.

One of the most critical concerns is the risk of downtime during retrofitting. In continuous-production industries, even brief interruptions can lead to missed targets, financial losses, or penalties. But this is not the case for all energy efficiency measures. For Organic Rankine Cycle (ORC) systems leveraging waste heat recovery to generate energy one of the major advantages is that the implementation is possible as retrofit in existing plant without disrupting ongoing industrial processes. ORC units integrate seamlessly with existing infrastructure, preventing the need for production stoppages and ensuring rapid installation and minimal maintenance.

Discover how our ORC solutions can be deployed in your process without interfering with your operations. Contact us.

Overcoming Infrastructure Barriers: Three Key Actions

ways and actions to solve and mitigate concerns and barriers related to integration into existing infrastructure.

- Build Trust in New Technologies Through Pilots

- Conduct in-depth energy audits with ESCOs or technology providers to establish performance baselines and identify upgrade opportunities.

- Select proven, fit-for-purpose technologies by consulting vendors and drawing inspiration from peers with similar use cases.

- Launch small-scale pilot projects to validate reliability and ROI, documenting challenges and outcomes. Use successful pilots as a basis for wider rollout across the organization.

- Optimize Facility Layout and Operations

- Implement preventive maintenance programs focused on the energy performance of existing equipment

- Identify opportunities to resize or reconfigure equipment based on audit data to improve efficiency and reduce waste.

- Roll out upgrades in phases to limit disruption and financial risk, starting with areas that show the most potential for impact.

- Support Change Management and Internal Skills Development

- Train staff on the operation of new energy-efficient equipment and data systems.

- Encourage cross-departmental collaboration—especially between operations, maintenance, and IT—to ensure smooth integration and long-term effectiveness.

2.3 Skills Gaps: A Human Factor Slowing Down Efficiency

While technologies and regulatory frameworks continue to evolve, many companies still struggle to improve energy performance due to a lack of internal expertise. For 15% of respondents, insufficient skills represent the top barrier to implementing energy efficiency initiatives.

This challenge stems from multiple factors: a shortage of technically skilled personnel, inadequate training programs, and cultural resistance to adopting new technologies. Nearly half of the surveyed leaders (48%) say that the lack of skilled workers limits their ability to identify and act on energy-saving opportunities. And among those who ranked skills as their top barrier, 68% specifically cited workforce limitations as a major constraint on implementation.

Collaboration among technology providers, industry associations, and academic institutions is key to identifying needs and offering opportunities for knowledge transfer to company staff. At Exergy, we work as a partner to our clients, accompanying them in any phase of an ORC implementation — from feasibility assessment and integration into existing industrial sites, to full technical support, training after implementation, and 24-hour after-sales service.

Energy efficiency demands a combination of technical, financial, and managerial competencies—from understanding energy audits and building systems to evaluating ROI and leading cross-functional projects. Yet many organizations lack dedicated energy managers or staff with the necessary mix of skills. Interestingly, larger companies tend to feel this gap more acutely, likely due to the complexity of their systems and the specialized expertise required for advanced projects.

Training plays a critical role in overcoming this barrier, but it is often neglected due to time, budget constraints, or low prioritization. Without structured upskilling programs, companies may fail to bridge the gap between old and new technologies, especially in industries where integrating modern systems into legacy infrastructure requires both technical depth and cross-departmental collaboration.

Overcoming Skills Gaps: Three Key Strategies

- Strengthen Training and Internal Knowledge

- Create focused training programs on energy systems, technologies, and best practices, and integrate them into onboarding and continuous learning.

- Partner with ESCOs or professional bodies to upskill employees on using new tools and platforms.

- Encourage Collaboration and Idea Sharing

- Join industry alliances to stay informed and exchange know-how.

- Set up internal platforms for employees to suggest efficiency ideas, and recognize impactful contributions.

- Bring in external experts when needed to cover specialized skills like data analysis or ROI modeling.

- Build Competence in Energy Management Standards

- Train staff on ISO 50001 or similar standards to support compliance and structure improvement efforts.

- Consider certification to validate practices and drive continuous energy performance improvement

2.4 Strategic Gaps: When Leadership and Vision Fall Short

While technology and funding are essential, energy efficiency also depends heavily on organizational strategy. For 12% of survey respondents, weak strategic alignment is the top barrier to progress.

A lack of strong leadership and clear energy-related goals often results in scattered efforts, limited accountability, and poor prioritization. When energy efficiency isn’t visibly supported by senior management, it’s often sidelined in favour of short-term financial or operational goals. In fact, 37% of respondents say their organization struggles to evaluate and prioritize energy efficiency actions based on impact and investment—especially in areas like manufacturing, buildings, or fleets.

In highly regulated industries, regulatory compliance can dominate attention and resources. Nearly half of those who ranked strategy as their top challenge say that time and budget spent meeting compliance requirements leave little room for proactive energy improvements.

Another major issue is the limited integration of energy efficiency into broader business KPIs—such as equipment performance or emissions targets. Without a formal energy strategy aligned with business goals, initiatives tend to remain fragmented and reactive. This is especially true for large organizations, where complexity and silos can slow down decision-making. Smaller companies, by contrast, may adopt energy efficiency more flexibly, with fewer layers of approval and quicker execution.

Overcoming Strategic Barriers: Aligning Vision and Execution

- Make Energy Efficiency Part of the Business Strategy

- Align energy goals with core business priorities like cost savings, ESG compliance, and risk management.

- Set clear KPIs for energy performance and embed them across departments and supply chain processes.

- Use recognized ESG reporting frameworks to track and communicate progress transparently.

- Strengthen Leadership and Accountability

- Assign energy efficiency ownership at the executive level and define clear roles and responsibilities.

- Create cross-functional teams to coordinate efforts across finance, operations, HR, and procurement.

- Tie energy KPIs to individual and team performance metrics to drive accountability and engagement.

- Integrate Energy into Daily Operations

- Embed energy practices into core business processes such as lean management, capital planning, and facility operations.

- Ensure energy is considered from the start in investment and design decisions.

- Involve suppliers in energy goals and explore options like power purchase agreements (PPAs) for stable pricing and clearer ROI forecasting.

2.5 Data and Control Challenges in Energy Efficiency

Another hidden obstacle to improving energy efficiency is the lack of robust data and control systems. 11% of the companies participating in the survey rank data control challenges as the top barrier to energy efficiency improvement. Many organizations struggle with poor data quality—such as inaccurate, incomplete, or infrequently collected energy usage information—which undermines informed decision-making. 46% of companies report difficulties in obtaining reliable energy data, making it hard to identify inefficiencies or justify investments. Additionally, fragmented or siloed energy management systems and limited investment in thorough energy audits further hinder progress. Despite this, some companies underestimate the need to enhance audit capabilities or invest in digital energy management solutions, creating a gap between regulatory compliance and proactive efficiency improvements.

Overcoming Data & Control Barriers to Industrial Energy Efficiency

- Build a reliable energy data collection system

- Identify key energy data needs and install IoT sensors on critical equipment to capture detailed consumption information.

- Establish strong data governance policies to ensure data accuracy, consistency, and security, possibly with external expert support.

- Use recognized ESG reporting frameworks to track and communicate progress transparently.

- Strengthen reporting and communication

- Provide frequent, clear updates to teams and leadership using dashboards and visuals that demonstrate energy savings and emission reductions.

- Promote success stories and best practices within the company to encourage wider engagement and improve organizational reputation.

- Develop targeted communication plans to share achievements with external stakeholders.

- Leverage advanced analytics for real-time insights

- Use AI and advanced data analytics to detect inefficiencies, unusual patterns, and energy trends.

- Automate report generation with actionable recommendations for operations and finance teams.

- Employ predictive tools like digital twins to simulate and evaluate potential energy-saving measures.

Conclusion

Industrial energy efficiency offers a clear pathway to lower emissions, reduce operational costs, and boost competitiveness—but internal barriers continue to slow progress. Financial constraints, outdated infrastructure, skills shortages, weak strategic alignment, and data challenges all play a role in hindering broader adoption. Yet, as the 2025 “Efficiency Now – Overcoming Internal Barriers to Industrial Energy Efficiency” report highlights, these obstacles are not insurmountable. Through targeted investments, stronger leadership, upskilling, and smarter data use, companies can unlock the full potential of energy efficiency.

Read the full report here!

Is your business ready for energy efficiency?

Contact our experts for a tailored solution!