- Application

- /

- HEAT RECOVERY FROM INDUSTRIAL PROCESS

Industrial Waste heat recovery

Industries account for almost 40% of total global energy use. Due to inefficiencies in their power conversion processes, around 20 to 50% of this energy becomes exhaust heat, which is unexploited and discharged into the atmosphere.

This represents a valuable resource that can be channeled into clean waste heat recovery, aka waste heat to power, systems. A Waste heat recovery unit captures the exhaust heat produced by industrial processes, such as exhaust gases from furnaces, boilers, and process heating equipment, repurposing it to generate clean electricity.

HARNESS UNTAPPED INDUSTRIAL WASTE HEAT TO GENERATE CLEAN ENERGY

Waste Heat Recovery with ORCs

Organic Rankine Cycle (ORC) is a technology ideally suited for industrial waste heat to power application. As opposed to waste heat recovery systems based on the traditional steam Rankine cycle, ORC delivers better efficiency for lower and medium-high temperature applications (from 90°C to 400°C), as well as eliminates the requirement for water treatment and makeup.

Why choose an ORC heat recovery system in the industrial sector?

1

INCREASE PROCESS EFFICIENCY

Waste heat recovery power plants help to achieve the highest industrial production efficiency.

2

REDUCE ENERGY COSTS

Waste heat recovery systems generate additional electricity for your plant, directly replacing purchased energy and thereby reducing energy costs.

3

INCREASE BUSINESS COMPETITIVENESS

Cutting energy costs contributes to reducing operating costs, increasing business profitability and competitive market advantage.

4

REDUCE ENERGY DEMAND

Waste heat recovery systems lower demand for conventional primary energy.

5

REDUCE CARBON FOOTPRINT

Waste heat recovery power plants use waste heat to produce electricity instead of burning fossil fuels, thus lowering SOx, NOx and C02 emissions.

6

REDUCE ELECTRICAL GRID DEPENDENCY

Waste heat recovery power plants ensure easier and reliable on-site access to electricity, an undoubted advantage for remote or isolated sites with difficult grid access.

Exergy’s use of the innovative Radial Outflow Turbine (ROT) in its waste heat-to-power solutions brings the advantages of ORC systems to a higher level, ensuring greater efficiency and lower specific costs, thanks to the following technical features:

higher ORC efficiency (up to 30%)

optimal match with the heat release curve

better operation at partial loads

Advantages of ORC systems for industrial waste heat recovery

1

SIMPLE PLANT DESIGN

Competitive capital cost leading to fast payback

2

COMPACT AND AUTOMATED SOLUTION

No need for operators

Lower operating costs

Smaller footprint

3

SEPARATE SYSTEM FROM THE MANUFACTURING PROCESS

Simple integration both in existing industrial process and greenfield plants

No impact on site operations

4

FLEXIBILITY OF PLACEMENT AWAY FROM THE HEAT SOURCE IF REQUIRED

No limitations or constraints on placement, better fit with available area and production process requirements

5

FAST START UP AND SHUT DOWN

Higher number of productive hours

Easy maintenance

6

NO WATER TREATMENT PLANT OR MAKEUP WATER REQUIRED

No need for water consumption

Higher sustainability

Suitable for remote locations

7

HIGH EFFICIENCY AT A VARIETY OF OPERATING TEMPERATURES AND LOADS

Possibility to exploit the maximum possible energy from the process, thus reducing energy costs

Industrial Applications of Waste Heat Recovery

Exergy’s ORC systems offer an efficient solution for industrial waste heat recovery across energy-intensive and diverse process industries. With quick deployment, these systems typically provide a payback period of just 3 to 6 years, making them highly effective for energy-intensive sectors. Exergy’s single units range from 1 MW to 20 MW and can be scaled up in modular systems to increase power output.

APPLICATIONS:

CEMENT PLANTS

STEEL MILLS

GLASS FACTORIES

OTHER INDUSTRIAL APPLICATIONS (PETROCHEMICAL,CHEMICAL, FOOD, ETC)

Want to know how we can help you unlock industrial waste heat potential?

PORTFOLIO

30 MWe

PLANTS

12

AVERAGE PLANT SIZE

2,5 MWe

TOE/Y SAVED

45000

TONNES CO2 EMISSION/Y SAVED

662174

Exergy's support for waste heat recovery projects includes:

TECHNICAL AND ECONOMIC ANALYSIS ON THE FEASIBILITY OF AN ORC SYSTEM APPLICATION BASED ON WASTE HEAT SOURCE DATA CHARACTERISTICS

ENGINEERING THE BEST TAILORED ORC CYCLE BASED ON CUSTOMER INPUT DATA

PROJECT MANAGEMENT

ORC EQUIPMENT MANUFACTURING AND ASSEMBLY

DELIVERY AND SUPERVISION DURING CONSTRUCTION

AFTER SALES SERVICE

Upon request, we can provide a turnkey solution for the whole WHR system (Intermediate circuit +ORC module).

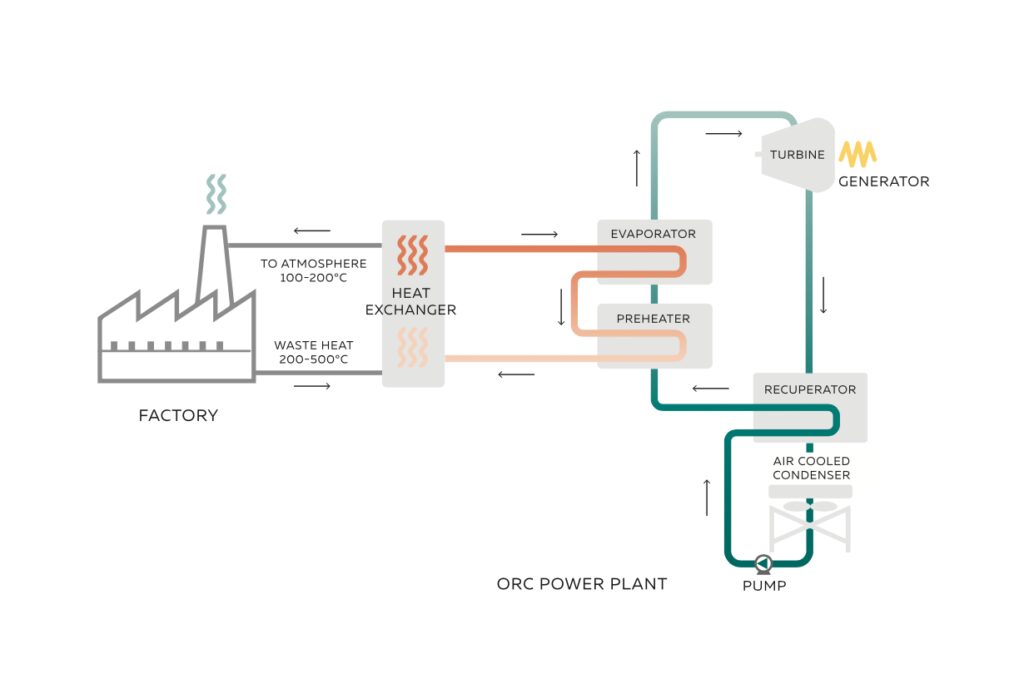

How an Industial Waste Heat Recovery cycle works

A waste heat recovery system extracts thermal power from the exhaust gas of the industrial plant to feed the ORC module via the intermediate fluid. This fluid, usually oil, pressurized water or steam, transfers heat to the organic fluid in the ORC evaporator, where it vaporizes. The vaporized fluid then passes to the turbine.

Here, the vapor expands, causing the turbine to spin and creating electricity in the generator. The vaporized organic fluid then continues through the cycle to the condenser where once again it becomes a liquid. It then passes through the pump before beginning the cycle again.

ORC waste heat recovery vs. traditional steam Rankine cycle technology: how to choose?

Regardless of the heat source temperature, ORC is generally the best solution for small power output. The simplicity and compactness of the system, higher efficiency of the turbine, optimal match with the heat release curve and better operation at partial loads ensure higher system efficiency and lower specific cost compared to conventional Rankine cycles.

In certain cases, they become the only practical solution.

Conversely, at considerably high temperatures and large power output, traditional Rankine cycles using steam turbines prove to be the ideal all-around solution: in these conditions, the limited increase in performance for heat sources available over 400°C for an ORC implies lower conversion efficiency.